In recent developments within medical imaging, a remarkable material known as cadmium zinc telluride (CZT) is making waves for its exceptional capabilities and the restricted number of manufacturers able to produce it. This semiconductor is revolutionizing the way we capture and process images in various applications including medical diagnostics, space exploration, and airport security. Notably, CZT is being utilized in advanced imaging devices at prominent medical facilities, such as the Royal Brompton Hospital in London, dramatically enhancing the efficiency of lung scans.

Traditionally, patients would endure lengthy examinations that demanded substantial stillness—often lying on their backs for up to 45 minutes. However, with the adoption of a new scanner equipped with CZT technology, this duration has been significantly reduced to just 15 minutes—a substantial improvement for patient comfort and throughput. The head of nuclear medicine and PET at the hospital, Dr. Kshama Wechalekar, emphasizes that this state-of-the-art equipment generates remarkably clear, three-dimensional images of patients’ lungs, facilitating timely and accurate diagnostics.

The scanner in question, featuring CZT manufactured by the British company Kromek, has garnered praise not only for its innovation but also for the efficiencies it introduces to nuclear imaging. Dr. Wechalekar highlights that Kromek is among a select group of firms globally capable of producing CZT, implying a high market demand for this critical material. In addition to its applications in healthcare, CZT is prized for its performance in other domains, including its role in X-ray telescopes, radiation detection, and security apparatus, making it an asset across various industries.

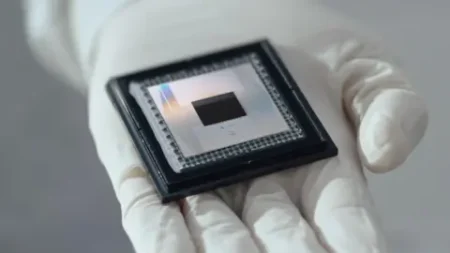

Despite the high demand, acquiring CZT remains a challenge. The material has historically been difficult to manufacture on a large scale, a fact acknowledged by Arnab Basu, the founding CEO of Kromek. In their facility located in Sedgefield, a meticulous process involving 170 small furnaces is employed to produce CZT from a special powder. This process entails heating the powder to create a molten state, followed by careful cooling to form a single-crystal structure. Over a period of weeks, atoms within the CZT are meticulously arranged to optimize their alignment.

The result is a semiconductor with unparalleled sensitivity to photon detection, capturing X-rays and gamma rays with remarkable precision. Traditional imaging systems relied on a two-step process, which lacked the clarity offered by CZT’s direct digital conversion method. This refinement allows for better quality images, including color and spectroscopic capabilities, proving advantageous in various applications, from healthcare to customs inspections at airports.

However, not all who seek CZT can easily obtain it. For instance, Dr. Henric Krawczynski from Washington University in St. Louis has encountered trouble sourcing the thin slices of CZT that are essential for his high-altitude scientific endeavors. His interest lies in utilizing CZT for telescopes designed to detect X-ray emissions from cosmic phenomena, such as neutron stars, but he faces constraints due to Kromek’s heightened demand amidst their expansion.

Furthermore, the field of scientific research utilizing CZT is significant. The £500 million upgrade of the Diamond Light Source in Oxfordshire, a synchrotron facility, stands to benefit from CZT detectors, which will enhance its ability to produce brighter X-rays. This advancement is crucial, as retaining detection capabilities commensurate with the anticipated increase in brightness is essential for success in ongoing experiments, including studies aimed at improving aluminum recycling processes.

In summary, cadmium zinc telluride (CZT) embodies a revolutionary force in medical imaging and other advanced scientific applications. With its multifaceted capabilities and the ongoing challenges faced in its production, the development and accessibility of this wonder material will be a focal point for industries spanning healthcare, aerospace, and beyond. As demand rises alongside technological advancement, the race to harness CZT efficiently continues to shape the future of diagnostics and exploratory science.